Pegahe Aftab Android Logsheet App

The Pegahe Aftab Logsheet software is a practical solution for accurately recording and monitoring equipment performance parameters in asset-intensive industries. With both online and offline access, it enables fast and error-free data entry, supporting effective analysis and utilization of the data in maintenance programs such as PM (Preventive Maintenance), CBM (Condition-Based Maintenance), and PdM (Predictive Maintenance).

Our Clients

What is Logsheet?

A logsheet is a paper-based or digital form commonly used in asset-intensive industries.

This form is used to record, collect, and retain equipment data during routine inspections, walkarounds, and regular checks of machinery and assets.

Each piece of equipment typically has its own dedicated logsheet. Maintenance and operations personnel use these forms—with predefined data fields—during routine rounds to record equipment-specific parameters such as temperature, vibration levels, flow rate, current (amperage), and similar metrics at scheduled intervals.

Collecting this information in logsheet forms—along with details such as the date of data entry, the person who recorded it, the approver, form ID, deviation levels, and more—provides maintenance and operations managers with a comprehensive overview of equipment conditions and the routine inspection activities performed.

Say goodbye to manual and paper-based logsheets.

What Is Logsheet Software and Why Does It Matter?

In many asset-intensive industries—such as power plants, steel manufacturing, refineries, petrochemicals, and beyond—routine logging and monitoring of key equipment performance parameters around the clock is essential. One of the core responsibilities of operations teams is to inspect critical equipment regularly and accurately record operational data such as temperature, vibration, pressure, or current.

Traditionally, many companies rely on manual data entry using paper-based logsheets. However, this method is time-consuming, prone to human error, and lacks the accessibility needed for timely data retrieval and effective analysis. Moreover, manually logged data often cannot be efficiently leveraged for triggering scheduled maintenance activities such as PM (Preventive Maintenance), CBM (Condition-Based Maintenance), or PdM (Predictive Maintenance). The sheer volume of recorded values and the need to sift through paper archives make data extraction both time-consuming and, in practice, nearly impossible.

The Pegahe Aftab Logsheet Software offers a reliable, efficient, and cost-effective solution to these challenges. Equipped with an Android application that supports both online and offline modes, it transforms the entire process of equipment data logging. From real-time data entry to report generation and actionable insights, the software delivers a fully integrated platform that automates the collection, storage, and application of operational data—helping organizations gain better control over asset health and maintenance planning.

Challenges of Manual Logsheet and Checklist Entries and Key Questions

Have you ever been able to fully utilize the data you painstakingly and regularly collect from critical and sensitive equipment multiple times a day?

Have you ever been able to provide this collected operational parameter data in real-time, effortlessly, to all authorized personnel, with no limitations on the date?

Have you ever had the ability to define formulas and schedule work orders (PM, PdM, CBM) based on the recorded values of these operational parameters?

How many days does it take for the data collected using various paper-based methods or existing handheld devices to be processed and made accessible to others?

Do you believe the current controls in place to ensure the accuracy of recorded equipment performance data—whether during entry by the operator or later checks by shift engineers and other experts—are reliable and comprehensive?

If you are using old equipment for recording device values: Have the numerous issues, such as a difficult user interface, challenges in data transfer, frequent port failures, and high maintenance costs, not become overwhelming for you?

The Power of Digital Logsheet and Checklist Registration

Recording Operational Parameters

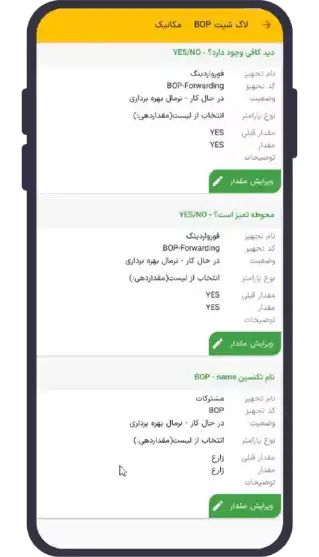

You can record operational parameters for the equipment tree you've configured in your maintenance system—fully tailored to your needs and with no limit on the number of hierarchy levels.

Centralized User Management

You can define as many users as needed for the Android Logsheet app on handheld devices. The entire process—from logging in, entering values, and confirming them, to submitting data—is fully controlled and traceable.

Custom Logsheet Templates

You can include multiple parameters from different pieces of equipment in separate logsheet templates, fully customized to your needs. Define as many templates (logsheet form designs) as required—there’s no limit to how many you can create.

Process Design Engine

You can define, design, and implement the entire process of data entry, review, and approval for logsheet forms—customized for each individual logsheet template if needed—using the Process Design and Execution Engine of the Power Plant ERP. In essence, you own a logsheet system with powerful process management capabilities, fully tailored to your operational workflows.

Logsheet Issuance Management

You can define your logsheet templates as case-based or, alternatively, choose a periodic type and set the interval period. With this setup, the system will automatically issue logsheet forms on a regular, around-the-clock basis, allowing you to focus solely on entering the data. The system handles the issuance and scheduling of log sheets, ensuring that no entries are missed.

Self-Control Management

The Logsheet system is designed with Self-Control features. This means that whether in offline or online data entry mode, the system performs the necessary checks and provides relevant alerts to the user regarding unauthorized values, trip limits, alarm thresholds, and other critical conditions. These real-time validations ensure that data entered is within acceptable ranges, enhancing accuracy and preventing errors before they are submitted.

Android and Desktop Platforms

You can enter data for logsheet forms either through the Android system using handheld devices or via a desktop computer in a desktop environment. There are no technical limitations when it comes to regularly and systematically entering values into the logsheet forms. The system ensures seamless and flexible data entry across both platforms, allowing for efficient and consistent logging regardless of the device used.

Push Method for Issuance

The method used for issuing logsheet forms is PUSH. This means that the user doesn’t need to manually search for which forms to fill out, with what parameters, and at what time. Instead, the system automatically pushes the relevant logsheet forms to the user. The user simply needs to log in to their portal inbox or access the Android Logsheet system with their credentials to see the forms that need to be completed. This approach simplifies the process, ensuring that users always have the right forms available when needed.

Support for All Types of PMs (Preventive Maintenance)

You can use the operational parameters associated with equipment in the definition of various Preventive Maintenance (PM) types. Once the values recorded in the logsheet are confirmed, they will be processed according to the defined workflow and become available as equipment parameters for calculating PM due dates. This ensures that maintenance schedules are automatically generated based on real-time, validated data, allowing for accurate and timely maintenance actions.

Types of Android Devices

You can use the Android Logsheet system on any smart device, industrial or non-industrial, that is equipped with Android 5.0 or higher, without any hardware dependency on Pegahe Aftab or any other brand. This provides you with the flexibility to integrate the system across a wide range of devices, ensuring compatibility and ease of use regardless of the specific hardware.

Automatic Data Synchronization

You can synchronize data with the server automatically or at the user's request via the WiFi network. Data transfer from the handheld device will have no delay. Within just a few minutes and with ease, all recorded values will be made available to authorized users. This ensures quick and efficient access to up-to-date information across all devices.

Complete Management and Auditing

You can reduce the time between data entry by the operator and the review and approval of logsheet forms from several days to just a few minutes. All logsheet forms, once filled out, are synchronized and then undergo the defined review and final approval process. This streamlines the entire workflow, ensuring faster and more efficient validation of the recorded data.

success stories

Yazd Taban Power Plant

One of the obvious needs at Taban Power Plant was to eliminate the manual logging of equipment data on paper log sheets. Manual and paper-based logging was a time-consuming process prone to errors in recording and processing the operational data of equipment. Additionally, it was essential to not only use software for equipment data recording but also to make the most effective use of this data in maintenance decision-making processes and actions. Moreover, it was important to ensure that reports required by each department were easily accessible to managers. After the implementation of the logsheet solution, Taban Power Plant was able to successfully achieve many of these goals and requirements.

Kahnooj Shobad Power plant

The Shobad Kahnuj Combined Cycle Power Plant, as the largest private investment in the southern part of Kerman province, was inaugurated in 2015 with the goal of supplying part of the electricity needed for the southeast region of the country, improving and stabilizing voltage, and enhancing the distribution and transmission network in southeastern Kerman. The implementation of the Logsheet software solution by Pegaah Aftab enables the plant to monitor equipment status precisely and access their performance history (and make decisions based on that data). This helps increase the reliability and lifespan of these valuable organizational assets, while also automating the maintenance and operational processes, improving work efficiency, and preventing resource wastage.

Features and Capabilities of Pegahe Aftab Logsheet Solution

Assigning Operational Parameters to Equipment Classes and Inheritance

Direct Assignment of Operational Parameters to Equipment in the Equipment Hierarchy Structure

Definition of Types of Instantaneous and Counting Numeric Parameters

Defining Allowed Range, Alarm Range, and Trip Range for Instantaneous Numeric Parameters

Determining the Increment Value Over a Period for Cumulative Numeric Parameters

Cumulative Numeric Parameters for Calculating Final Value When Overflowing Meter Data During Logsheet Entry

Designing Logsheet Templates Based on Equipment Operational Parameters

Designing Logsheet Templates Based on Equipment Operational Parameters

Designing the process of recording, reviewing, and final approval of logsheet values.

Designing case-based and periodic logsheet forms with the ability to set the start date and frequency in minutes, hours, and days.

Defining different logsheet issuance stations according to each form template.

Automatic issuance of periodic logsheet forms by the system at their due date.

Creating tasks in the task inbox for issued logsheet forms based on the assigned issuance station.

The ability to install and use the Android logsheet app on all handheld devices and smartphones equipped with Android 5 and higher.

Assigning users to the logsheet app on each handheld device.

Login of authorized users to the Android app on the handheld device.

Why Pegahe Aftab?

Pegahe Aftab has been specializing in the development of software solutions for equipment-centric industries since 1999. Some examples of their work include the power plant ERP, maintenance and repair solutions, and the logsheet software.

At Pegahe Aftab, we take great pride in our human capital. We believe that our solutions are the result of the innovation and expertise that come from combining the skills of our software development teams with a deep understanding of industry concepts.

Over two decades of partnership with major industries and providing excellent software services is an achievement that ensures a path of service to future customers.

FAQs

Everything You Need to Know to Get Started

Is an industrial handheld device required to use this solution?

No! This solution runs on all Android devices with Android 6 or higher, and there is absolutely no need to purchase any specific device.

Is data transfer done via cable?

No! Data transfer via cable is time-consuming and effectively prevents the collected data from being quickly shared with stakeholders. Moreover, using connection cables reduces the lifespan of equipment data logging devices. In the Pegahe Aftab logsheet solution, data is transferred wirelessly without requiring any user intervention.

Is using this solution dependent on purchasing Pegahe Aftab's maintenance and repair system?

No! The Pegahe Aftab Android Logsheet solution operates independently and does not require any maintenance software to function. However, using both systems together offers significant benefits to the customer.

Does this solution support integration with maintenance and repair systems?

Yes. The Pegahe Aftab Logsheet software can be fully integrated with the Pegahe Aftab Maintenance Management System.

In which industries can the Pegahe Aftab Android Logsheet be used?

The Pegahe Aftab Logsheet solution can be used across all asset-intensive industries, including refineries, the steel industry, mining, power generation, manufacturing, automotive, food industries, and any other sectors that routinely and regularly log operational equipment data.

Is the Pegahe Aftab Logsheet solution only operable on mobile devices?

No. In many cases, logsheet entries are made in the control room. Such logsheets can be filled out using the Pegahe Aftab desktop logsheet application.