Pegahe Aftab CMMS Solution

The various modules of Pegah Aftab’s CMMS Solution provide an infrastructure for the integrated management of all maintenance activities and related equipment, offering maintenance operators and managers a comprehensive toolset.

Our Clients

Pegahe Aftab CMMS Solution

In 2001, the CMMS Solution was developed as Pegah Aftab’s first product, commissioned by one of the country’s power plants. Over the years, the evolution and development of Pegah Aftab’s maintenance solution have been such that it is now recognized as a comprehensive tool for managing physical assets across various industries. To date, Pegah Aftab has proudly collaborated with dozens of organizations nationwide.

Pegah Aftab’s CMMS Solution is equipped with modules for equipment management, maintenance planning, work request and work order management, work permits, process workflow management, maintenance human resource management, HSE (Health, Safety, and Environment) management, maintenance and repair projects, dashboards, and analytical reports. Additionally, the use of advanced technologies such as process management engines has enabled this solution to provide the necessary tools for comprehensive, integrated, and goal-oriented management of machinery and equipment, making it possible to leverage modern maintenance strategies.

Additionally, Pegah Aftab’s CMMS Solution can be integrated with specialized modules of its Enterprise Asset Management (EAM) solution, including document and electronic archive management, spare parts and consumables inventory management, supply chain management for goods and services, and an Android-based mobile data collection solution (logsheets and checklists).

CMMS Solution in Various Industries

Manufacturing Plants

Pegah Aftab's CMMS Solution offers a cost-effective way for manufacturers to enhance equipment reliability, work completion rates, the turnover of repair parts, and more.

Oil and Gas Industry

Given the extensive and complex equipment often installed in remote and hard-to-reach locations, effective maintenance and repair management without the right tools can be challenging, time-consuming, and highly error-prone and risky.

Food Industry

Health and safety are paramount in the food industry, and adhering to its stringent standards is nearly impossible without leveraging a robust CMMS system.

Healthcare Industry

Healthcare facilities and the health industry require maintenance and repair management for critical assets such as generators, sterilization equipment, X-ray machines, air purifiers, and more.

Warehousing and Distribution Industry

A CMMS Solution tailored for the warehousing industry helps streamline maintenance processes and minimize equipment downtime.

Steel Industry

CMMS enables companies to plan and schedule preventive maintenance more effectively. This helps reduce unexpected breakdowns and extends the lifespan of equipment.

Modules of Pegahe Aftab's CMMS Solution

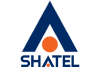

Define and track the documentation of your equipment and physical assets based on various standards such as ISO 14224, KKS, AKS, and more, managing them throughout their lifecycle. Additionally, with Pegah Aftab’s CMMS Solution, you can easily view and manage all maintenance-related information in one centralized location.

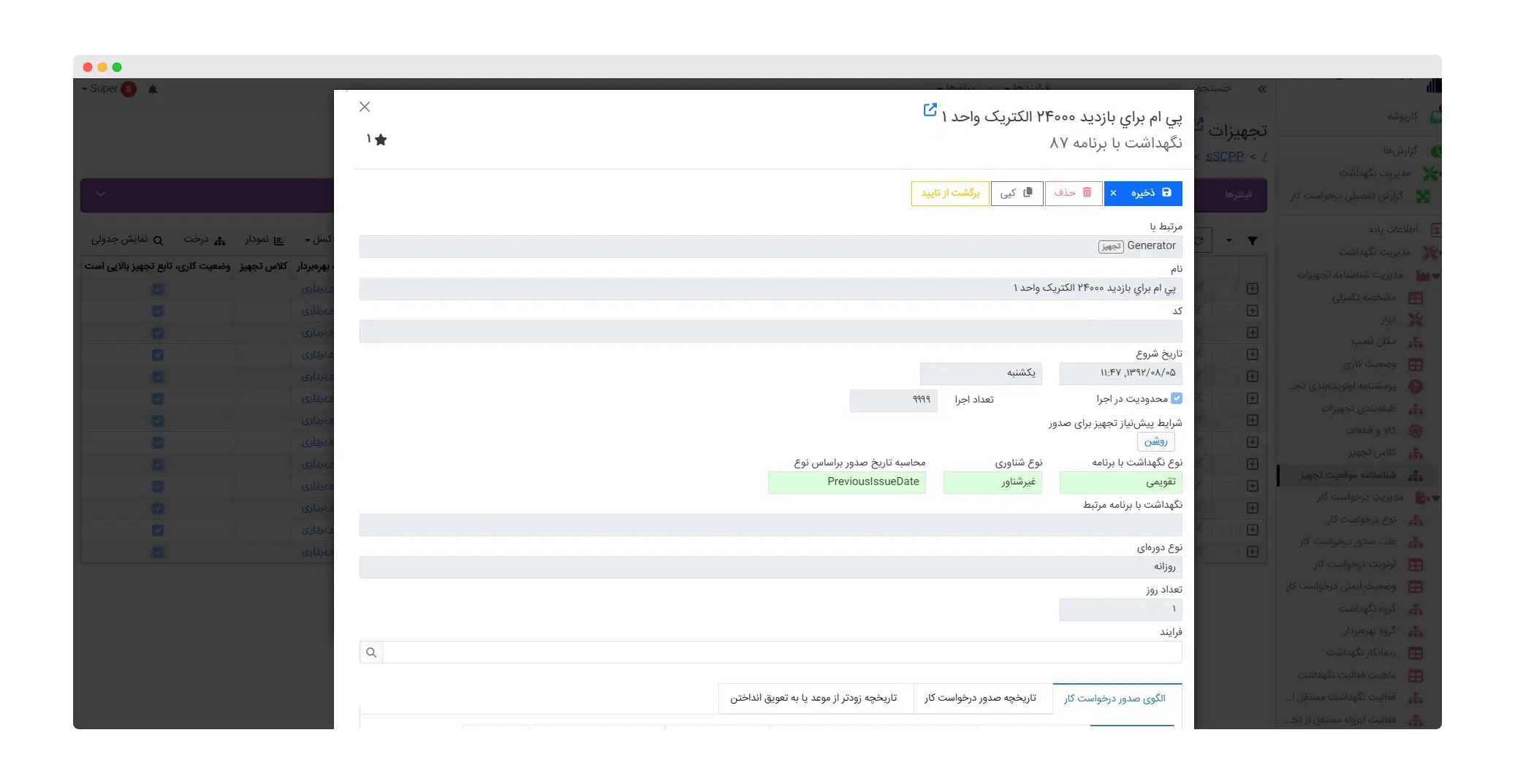

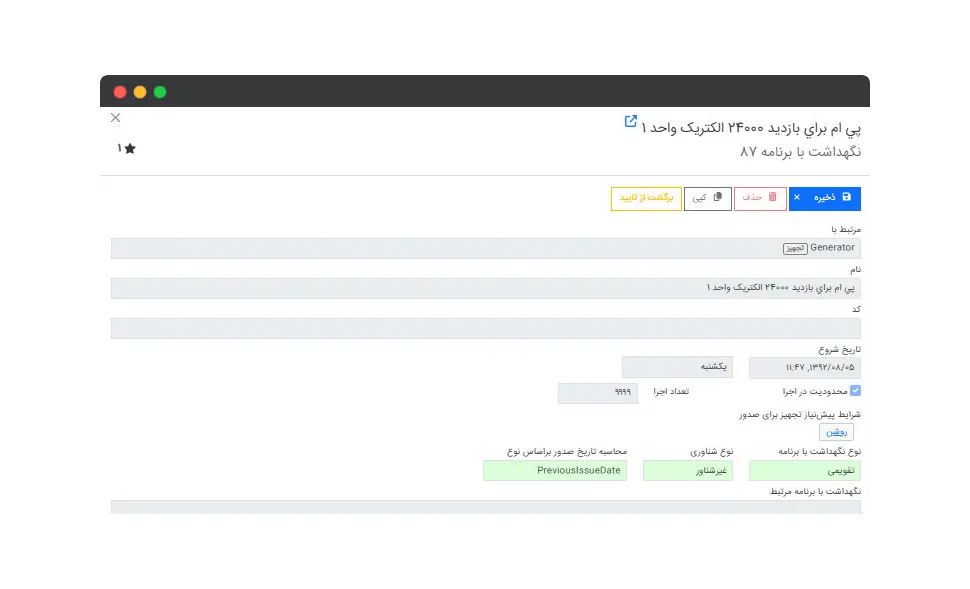

In Pegah Aftab’s CMMS Solution, you can prioritize equipment based on key decision-making criteria, determine their importance levels, and implement maintenance strategies—from reactive to proactive—tailored to your needs. You can also take control of managing PMs (Preventive Maintenance), CBMs (Condition-Based Maintenance), PdMs (Predictive Maintenance), and various maintenance projects.

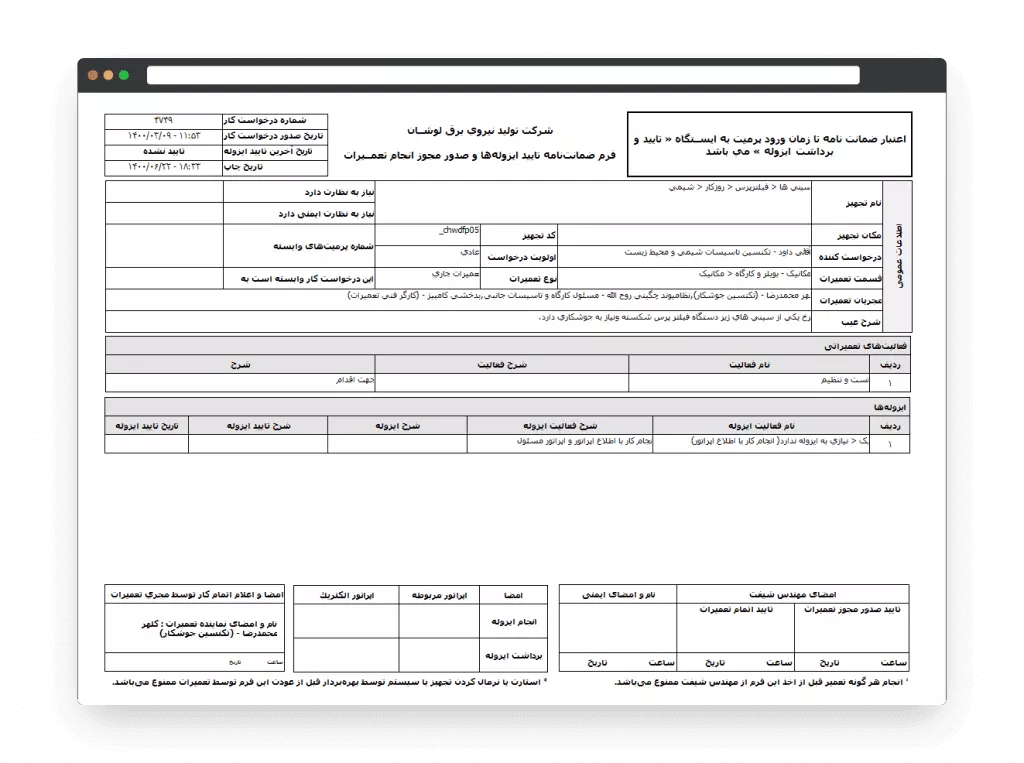

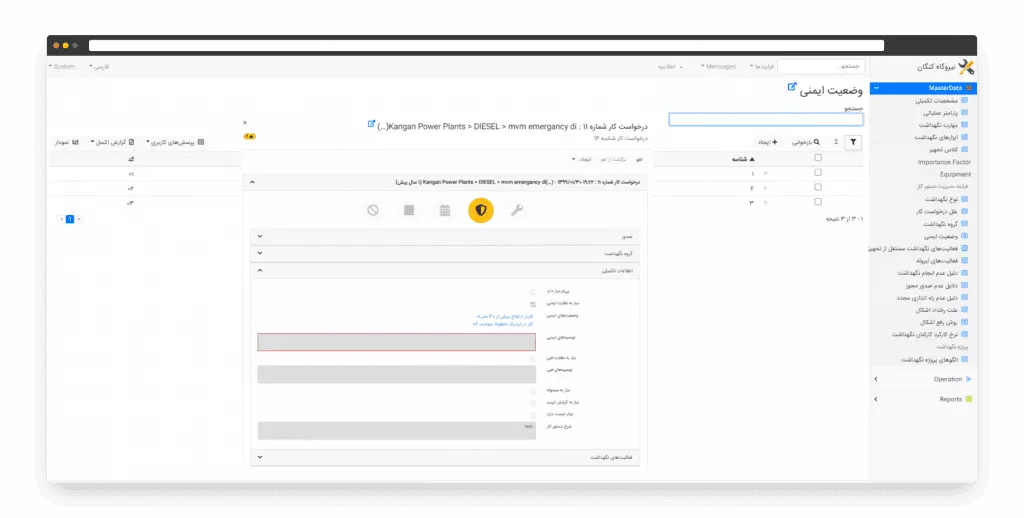

With Pegah Aftab’s CMMS Solution, you can easily manage all stages from issuing to approving work requests, coordinating, and executing work orders digitally and paperlessly. Additionally, in a fully integrated environment, you can monitor all activities of stakeholders involved in work requests and create a centralized digital hub for permanent storage of work requests. At any time, you will have instant access to various operational and analytical reports on work history, costs, failures, and other information.

If you are involved in maintenance and repair activities in industries such as power plants, refineries, petrochemicals, and similar sectors, you can use the Work Permit module of Pegah Aftab’s CMMS Solution to implement and execute all stages and necessary information for isolations, simulations, and issuing permits (guarantees) for work requests.

With just a few clicks, graphically design the workflow for work request and work order processes. Easily define the necessary rules and conditions without requiring programming knowledge, and utilize the work folder features to streamline planned activities. You can also modify your workflow at any time with ease.

Pegah Aftab’s CMMS Solution enables the integration of safety, occupational health, workplace hygiene, and environmental protection guidelines based on implemented standards such as OHSAS 18001, ISO 45001, and ISO 14001.

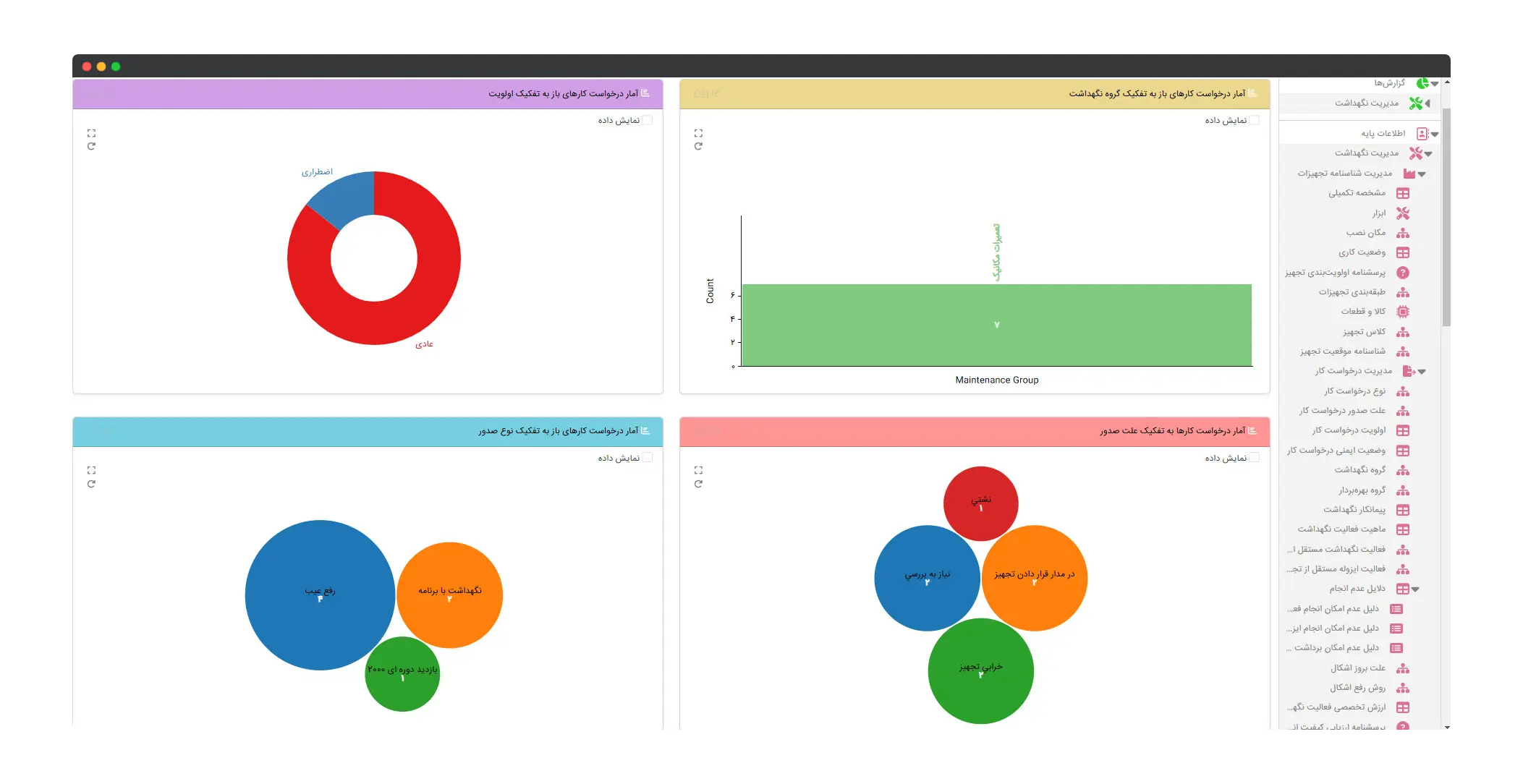

Easily extract information from various maintenance and repair management sections using pre-built reports, and design the dashboards you need based on different KPIs within minutes for more comprehensive analysis. You also have the ability to manage user access to report outputs using access level settings and, if needed, export reports in Excel, Word, and other standard formats.

Features of Pegah Aftab's CMMS Solution

The diverse features of Pegah Aftab’s CMMS Solution modules provide an infrastructure for the integrated management of all maintenance activities and related equipment, offering maintenance operators and managers a comprehensive toolset. Additionally, these features empower decision-makers to implement various maintenance strategies, enabling each organization to adopt the most suitable strategy in the CMMS software based on its specific needs, organizational culture, equipment type, workforce size, and budgetary requirements.

- Process Management Tool; with the ability to dynamically and operationally design workstations and their connections

- Ability to Define Attachment-Type Workstations

- Ability to Define Shared Workstations Among Workstation Users

- Ability to Define Exit Conditions on Workstations

- Ability to Define Filter Conditions on Each Workstation

- Ability to Recall Sent Tasks by the Task Sender

- Ability to Return Tasks to the Sender with Specified Return Levels

- Ability to Attach Files to Tasks

- Ability to Enforce Task Review Before Removing Tasks from the Work Folder

- Ability to Enforce Task Review Before Removing Tasks from the Work Folder

- Ability to Define Codes for Each Workstation

- Ability to Search Workstations and Their Connections

- Ability to Set “Exit with Approval” and “Exit without Approval” Conditions Without Entering the Condition Environment

- Ability to Save Processes to Apply Changes from the Process Design Environment to the System

- Ability to Set “Access Levels to Form Components” for Each Workstation

- Report Design Tool; for Creating Custom Reports in Both Digital and Paper Formats

- Portal Menu Design Tool

- Access Level Configuration Tool

- User Management

- Portal

- Defining Planned Maintenance for Equipment Classes or Equipment Trees

- Coverage of Various Planned Maintenance Types: Preventive, Condition-Based, and Predictive

- Planning Periodic and Risk-Based Inspections

- Using Equipment Operational Parameters to Define Formulas for Issuing Planned Maintenance

- Automatic Calculation of Pms Deadlines Based on Calendar Definitions or Formulated Formulas, Considering Equipment Operational Parameters or Equipment Status Change History

- Systematic Issuance of PMs Work Orders at Deadlines

- Defining the Work Request Issuance Pattern for PMs

- Defining Operator Sections and Assigning Users to Each Section

- Defining Maintenance Sections and Assigning Supervisors and Executors to Each Section

- Defining Work Shifts and Assigning Employees to Each Shift

- Defining Skills and Job Roles

- Setting Hourly Wages for Each Maintenance Employee

- Assigning Executors for Each Active Work Request or Planned Work Request

- Defining the Template for Equipment Maintenance Projects

- Defining Equipment Maintenance Projects Based on Programmatic Data

- Announcing the Operational Start of the Project

- Automatic Issuance of Project Work Requests Based on Defined Precedence Relationships

- Defining Equipment Classes with a Tree Structure

- Defining Maintenance Activities for Each Equipment Class

- Assigning Documentation to Each Equipment Class

- Defining Various Types of PMs for Equipment Classes

- Defining the Tree Structure of Equipment

- Inheriting Documentation Information from the Assigned Equipment Class

- Determining Equipment Installation History in the Tree Structure

- Determining Equipment Installation Locations Using the Tree Structure

- Defining Isolation, Simulation, Safety, and Environmental Activities Independent of Equipment Class

- Defining Interlock and Auxiliary Equipment

- Defining Equipment Documentation Independent of Class

- Recording Equipment Calibration History

- Recording Asset Management Information for Equipment

- Recording Equipment Status Change History

- Automatic Recording of Status Change History via Signal Transmission System

- Recording Status Change History via Logsheet System

- Defining Various Types of Equipment Operational Parameters

- Assigning Appropriate Tags in the Signal Transmission System to Each Operational Parameter

- Identifying Goods, Consumables, and Spare Parts for Equipment from the Supply Chain Management System’s Item Bank

- Managing Equipment Procurement and Manufacturing Information

- Determining Equipment Priority and Importance Based on Safety, Maintenance and Repair, Environmental Impacts, Production Effects, or Organizational Preferences to Adopt Appropriate Maintenance Strategies

- Designing Work Order Management Processes Using the Infrastructure Capabilities of the Process Design Environment

- Covering Activities in Areas Such as Operations and Production, Maintenance, Technical and Engineering, Planning, Safety and HSE, Maintenance Contractors, and More During Process Design and Execution

- Designing Fully Integrated Work Order Management Processes with Support Management and Supply Chain Processes for Goods and Services

- Batch Import of Work Orders from Excel Files or Other Data Formats for Bulk Issuance of Multiple Work Orders with Defined Starting Workstations

- Issuing Dependent Work Orders and Executing Them Within the Designed Process

- Calculating Direct Costs of Consumables and Spare Parts for Work Order Execution

- Calculating Direct Labor Costs for Maintenance Executors of Work Orders

- Calculating Aggregate Costs of Goods and Labor for Work Orders and Applying Overhead Costs

Benefits of Using Pegahe Aftab's CMMS Software

FAQs

Answers to your questions about Pegah Aftab’s CMMS Solution are here.

What modules are included in Pegahe Aftab's CMMS Solution?

Equipment Management Module

Maintenance Strategy Management Module

Work Request and Work Order Management Module

Work Permit Module

Process Workflow Management Module

Health, Safety, and Environment (HSE) Module

Dashboard and Analytical Reports Module

Failure and Emergency Maintenance Management Module

Contractor Management Module

Inventory Management and Warehouse Accounting Module

Warranty Management Module

and …

What is the deployment model of Pegahe Aftab's CMMS Solution?

Pegah Aftab is prepared to deliver the CMMS Solution in various formats based on user needs and demands, including as a web-based solution, a cloud-based SaaS solution, or an on-premise Windows solution.

Does Pegahe Aftab's CMMS Solution have the capability to generate real-time reports?

Absolutely. Pegah Aftab’s CMMS Solution enables businesses of any size to transform relevant data into actionable reports in the shortest possible time. Various reports, from budgeting and scheduling to equipment lifespan and personnel updates, will be delivered to defined stakeholders with frequent, rapid updates and easy access.

Does Pegahe Aftab's CMMS Solution help integrate tools and improve workflow?

Absolutely. Pegah Aftab’s CMMS Solution enables businesses of any size to transform relevant data into actionable reports in the shortest possible time. Various reports, from budgeting and scheduling to equipment lifespan and personnel updates, will be delivered to defined stakeholders with frequent, rapid updates and easy access.

Does Pegahe Aftab's CMMS Solution help integrate tools and improve workflow?

Yes. Pegah Aftab’s CMMS Solution supports companies across all aspects of the asset lifecycle, from procurement to deployment, equipment management, physical asset tracking, maintenance, and more. Therefore, you won’t need separate systems to manage different aspects of physical asset workflows.